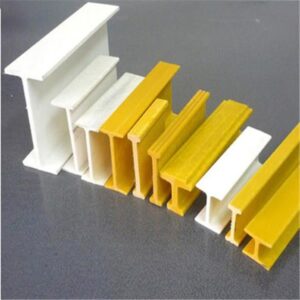

FRP Pultruded Profiles — Lightweight. Corrosion-Resistant. Long-lasting.

What: Pultruded fiberglass (FRP) structural shapes and rods used across infrastructure, marine, chemical, and civil projects. Why: Superior corrosion resistance, high strength-to-weight ratio, non-conductive properties, and low maintenance — ideal where metal corrodes fast.

FRP Pultruded Profiles — Types Overview

Below is a concise list of common pultruded fiberglass profile types. Each entry links to a deeper product cluster (replace hrefs with your product cluster pages).

FRP Pultruded Round Tube

Hollow circular tubes offering lightweight stiffness and torsional resistance. Common for conduit, shafts, and structural members where a smooth round cross-section is required.FRP Pultruded Rectangular Tube

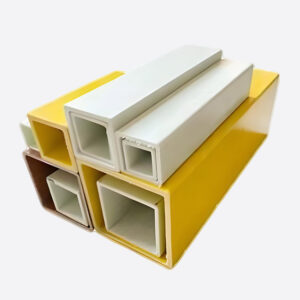

High moment of inertia in bending for rectangular sections; widely used in railings, frames and platforms where flat faces and easy attachment are needed.FRP Square Tube

Square hollow sections for modular frames, supports and barrier posts — easy to connect with brackets and fasteners for prefabricated assemblies.FRP I Beam

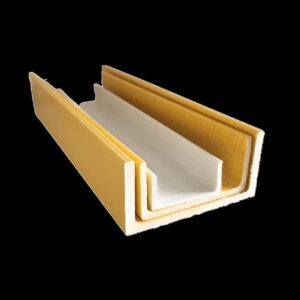

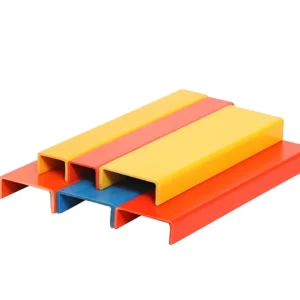

Pultruded I-sections engineered for bending loads with low deflection; excellent for bridge components, decking supports and long-span structures in corrosive environments.FRP U Channel

U channels for mounting, edge protection and as guides in skid rails — combine strength with lightweight handling and corrosion resistance.FRP Angle

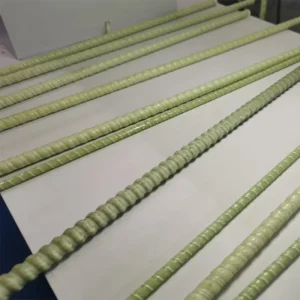

Angle sections for frames, bracing and trim — used where cost-effective stiffening with easy bolting is required in corrosive atmospheres.Fiberglass Rebar (GFRP Rebar)

Non-metallic reinforcement for concrete with high tensile strength and superior corrosion resistance, used in coastal, chemical and high-humidity structures.Materials Comparison — FRP Matrix & Reinforcement Options

Quick reference to compare common resin systems and reinforcements for pultruded profiles.

| Material / Property | Typical Properties | Common Applications | Pros | Cons |

|---|---|---|---|---|

| Polyester Resin (Orthophthalic / Isophthalic) | Good general corrosion resistance; economical | General structural profiles, decking, channels | Low cost; good UV variants available | Lower temperature resistance; moderate chemical resistance |

| Vinyl Ester Resin | Improved chemical and fatigue resistance vs. polyester | Chemical tanks, marine components, pultruded beams | Better corrosion resistance and longer service life | Higher cost than polyester |

| Epoxy Resin | Excellent mechanical & thermal properties | High-performance structural parts, aerospace | High strength, excellent adhesion | Costly; more complex processing |

| Reinforcement: E-glass (unidirectional) | High tensile strength along fiber; good stiffness | Beams, rods, rebar, load-bearing profiles | High strength-to-weight; cost-effective | Lower compressive strength vs some specialty fibers |

| Reinforcement: Carbon fiber (hybrid) | Very high stiffness & low CTE | Lightweight high-stiffness pultrusions | Minimal deflection; excellent fatigue performance | Expensive; may be overkill for routine use |

| GFRP Rebar (pultruded) | High tensile, non-corroding | Concrete reinforcement in marine/chemical exposures | No corrosion, electromagnetic neutrality | Different bond behavior to concrete vs steel — design adjustment needed |

Tip: Choose resin first (based on chemical/temperature exposure), then reinforcement architecture for load direction and stiffness requirements.

- FRP Profiles

FRP Rock Bolts

- FRP Profiles

FRP Cable Tray

- FRP Profiles

Pultruded Fiberglass Square Tubing

- FRP Profiles

FRP Pultruded Channel

- FRP Profiles

FRP Structural Tube

- FRP Profiles

Fiberglass Wide Flange Beams

- FRP Profiles

Structural Fiberglass Beams

- FRP Profiles

Fiberglass Wood Beams

- FRP Profiles

Structural Fiberglass Angle

- FRP Profiles

Fiberglass 90 Degree Angle

- FRP Profiles

Reinforced Fiberglass Angle

- FRP Profiles

5 ft long to 12 ft long FRP rod

- FRP Profiles

FRP Angle Bar

- FRP Profiles

FRP U/C Channel

- FRP Profiles

FRP I Beam

- FRP Profiles

FRP Square Tube

- FRP Profiles

FRP Rectangular Tubes

- FRP Profiles

Pultruded Fiberglass Round Tubes

- FRP Profiles

FRP Rod

Selection Guide — Quick Decision Tree

Follow this simplified flow to select the right FRP pultruded profile.

Notes: For structural spans check flexural modulus and section modulus; for concretes use GFRP rebar with correct bond profile (consult our tech team).

Industry Standards & Common HS Codes

- EN 13706 — European standard covering pultruded structural composite profiles, including dimensional tolerances and load-bearing guidance.

- ASTM series — Typical test standards used for pultrusions include ASTM tensile/creep/flexural methods (e.g., ASTM D638 for tensile testing; industry pultrusion practices reference relevant ASTM methods).

- ISO / National Guidelines — ISO and national standards (e.g., ISO guidance for FRP in infrastructure and CSA S806) are commonly used for structural design verification.

Common HS / HTS codes used in trade (examples)

Classification varies by jurisdiction and exact product form. Commonly used headings for pultruded FRP profiles and GFRP rebar include:- 3916.90 / 3921.90 / 3926.90 — Plastic rods, profiles, and other shaped articles are frequent classifications for pultruded profiles in many customs rulings. (Check local tariff notes and provide product technical datasheets to customs broker.)

- GFRP Rebar — Often classified under 3916.90 or similar “plastic rods/profile” headings depending on country practice — always confirm with local customs.

If you need, we can produce a customs-ready datasheet listing recommended HTS/HS codes per destination country — request via the quote button.